How can we guarantee the quality of the products we manufacture? Basically, we use the following treasures and processes to ensure that we always deliver high quality products to our customers.

Design Rules Check (DRC)

The DRC is a quite important step and in-depth review of your production data in our segment of manufacturing, which is carried out by our experienced CAM engineers with GENESIS software before the production. A comprehensive Design Rule Check helps to identify any errors in advance, thus avoiding problems and complaints.

Automated Optical Inspection (AOI)

We use AOI to check the component related defects. This inspection is much more reliable and repeatable than manual visual inspection and it will guarantee high reliability. AOI visually scans the surface of the PCB. The circuit board is lit by several light sources and observed by a scanner or by a number of high definition cameras. This enables the monitoring of all areas of the printed circuit board. As PCB is the backbone of all our products; AOI for a bare PCB board inspection will detect the features include:

- Line width violations

- Spacing violations

- Excess copper

- Missing pads

- Cut traces or pads

- Hole breakage

X-Ray

Testing the layer offset with X-ray technology is very important in manufacturing our product segment. X-ray images are the best (and only) way to identify and correct layer displacements in the pressing process.

Drill holes in multilayer PCB are also optimized using X-ray images. Any minor deviations in the geometry of the circuit board image compared to the geometry of the drill hole coordinates will be identified. By changing a correction factor within a clearly defined tolerance range, it can be ensured that the optimum drill reference point will be determined for each axis, with an optimal interpolation for all layers. These corrections take place in the µm range!

Certificates

ISO 9001:2018

ANSI ESD S20.20

ISO 14001:2015

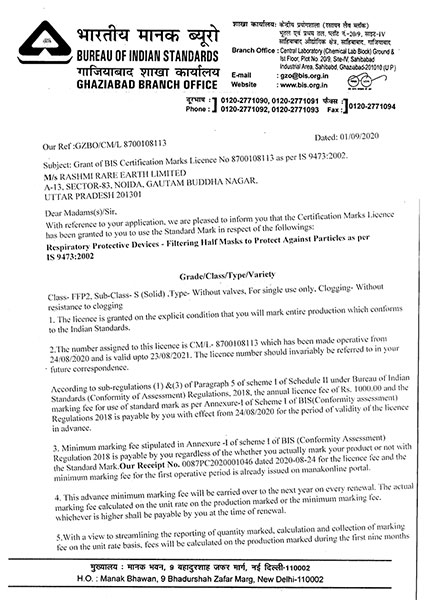

BIS (Bureau of India Standard)

The other Reliability Testings before shipment as below

Plating thickness testing

Surface peelable testing

100% Visual inspection

Ionic contamination testing

Thermal stress testing

Impedance testing

Solderability testing

Metallographic microscopic analysis

Certificates